Flush Diaphragm Seal

Flush Diaphragm Seal

Features

Process fluids which are highly viscous or containing solid particles could plug or clog the Diaphragm Seal cavity on the process side of the diaphragm. In order to overcome this difficulty, Flush Diaphragm Seal are used. In this design, since the Diaphragm is directly welded on the Flange Face, there are no cavities or hidden ports where the process fluid can enter and clog the system.Optionally, Flushing Ring (Spacer Ring) with 1/4" NPT(F) or 1/2" NPT(F) connection can be provided as per the requirement. Flushing Connection enables the user to purge / flush out / clean the area below the diaphragm without removing the Seal from the process line.

Optional Feature

- Cooling Tower

- Capillary for Remote mounting of the Pressure Instrument

- Flushing Ring (Spacer Ring) for purging / cleaning the area below the diaphragm without removing the Seal from the process line.

- Stud / Nut & Gasket (for Flanged Connection only), for assembling the Diaphragm Seal with Process Flange.

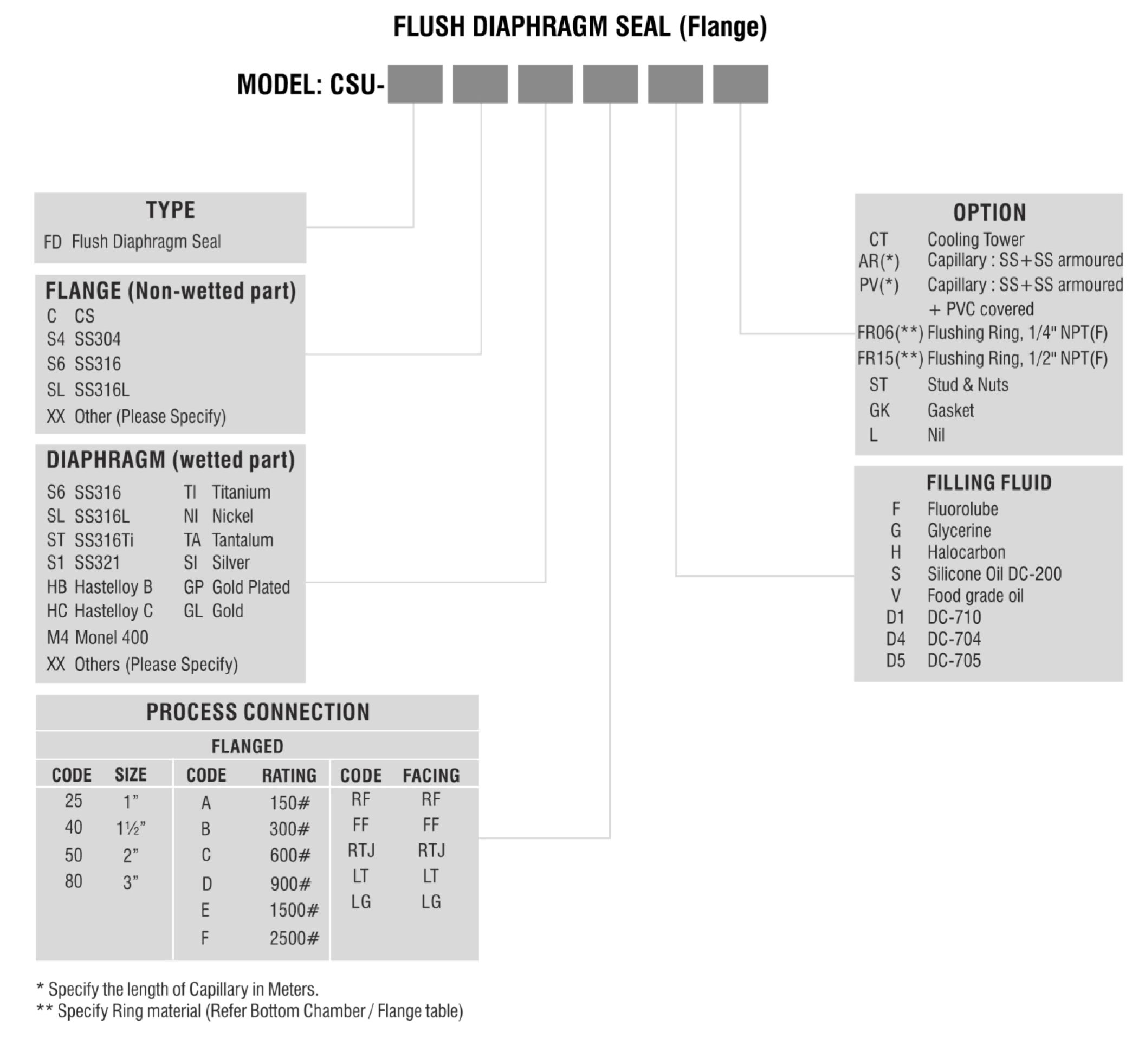

Ordering Information