Stainless Steel Pressure Gauges

Mahalaxmi Instruments offer “MASTER” make stainless steel Pressure gauges. All stainless steel Pressure gauges are best suited for use in application involving corrosive process fluid coupled with hostile and corrosive environment.

To meet different applications all stainless steel gauges are manufactured in pressed steel and weatherproof bayonet lock case.To meet application with mechanical vibrations gauges are available in glycerin filled case.

Fulfill the requirements of power and allied industry. Stainless steel pressure gauge offers resistance in corrosive environments and modes. Stainless steel pressure gauges are available in any size from small to large.

Catering to the requirements of power and allied industry, we offer quality array of Stainless Steel Pressure Gauges. Renowned for offering resistance in corrosive environments and modes, these find wide application in power generation, pollution control equipment, chemical & petrochemicals and oil exploration. These gauges are available in 63mm, 100mm & 150mm sizes and can be customized as per client requirement.

Specifications

| Dial Sizes | (40mm, 50mm, 63mm, 100mm, 150mm, 250mm) |

| Accuracy | 1 to 2% F.S.D |

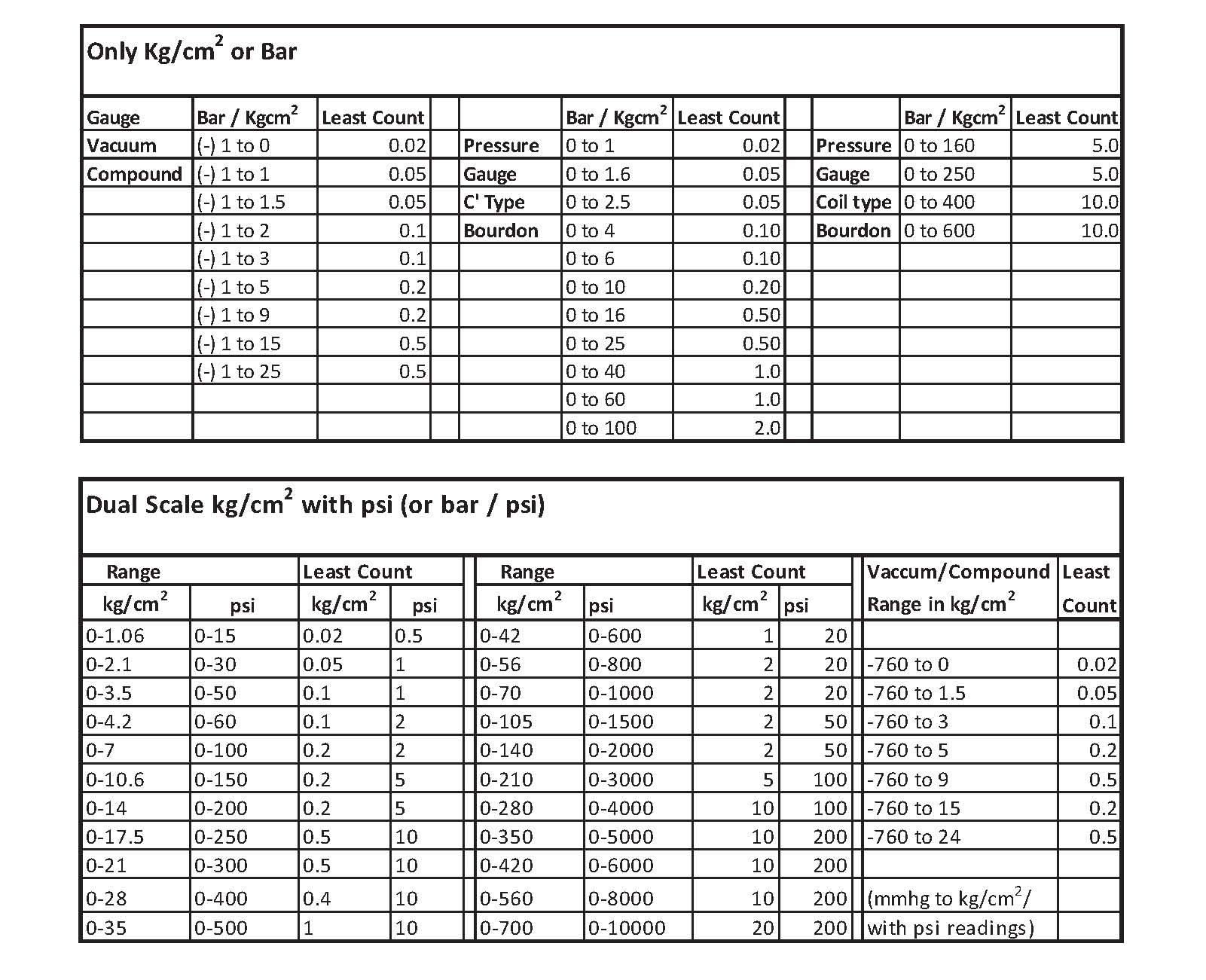

| Ranges | Std. Ranges from 0.1 upto 700 bar or kg/cm2 (10000 psi) & vaccum, compound ranges |

| Case & Ring | SS 304, SS 316,(Pressed Type/Byonet type) |

| Socket | SS 304, SS 316, SS 316L, Monal, SS 316TI 'C' shaped Tube upto 70 Bar 'C' shaped Tube upto 70 Bar |

Coil Shaped Tube above 70 Bar.

| Movement | SS 304 |

| Over Pressure Limit | 1.3 times of Full Scale Pressure |

| Joints: | ARC Arogan lded |

| Windows: | Glass |

| Pointer | Micro Zero adjustable, plain pointer |

| Pointer | Micro Zero adjustable, plain pointer |

| Connections: | 1/8, 1/4, 3/8, BSP or NPT |

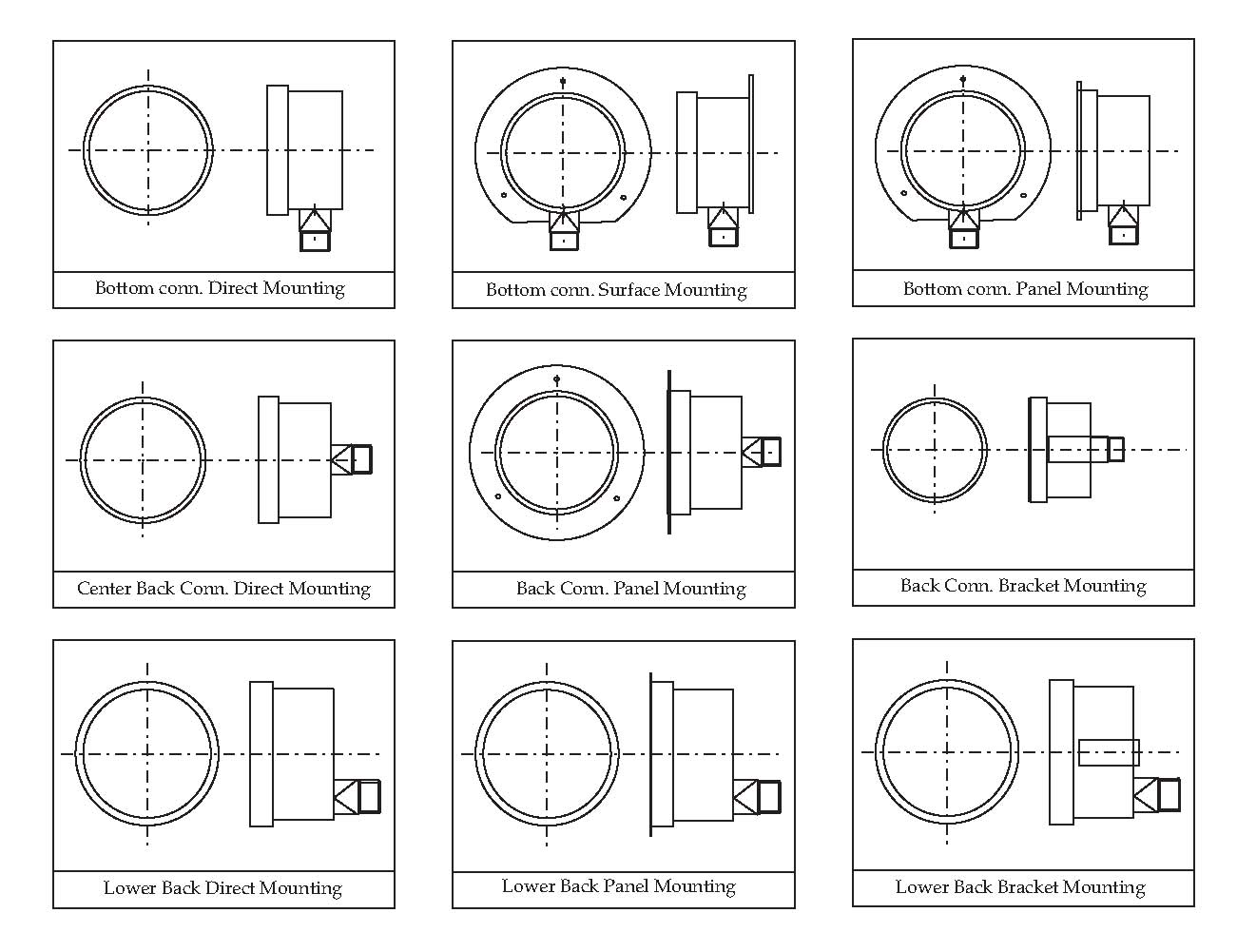

| Mounting: | Bottom, Bottom Surface, Back, Back Panel, Back Clamp |

| Options available: | Glycerin Filling: |

Application

- application in power generation, pollution control equipment, chemical & petrochemicals and oil exploration.

- Stainless Steel Gauges are used for corrosive media & challenging ambient environment

- voids leakages and provides integrity to the gauge. Liquid filling option is available for applications with vibrations.

Mounting Information

Range Selection